Next, pull the dash and plum AC/heat vents and get that all working. Most of the body work is done I just need to convince the wife to let me paint it.

stock stuff is still there.Rmc wrote:U gonna re-use the stock ac/heat stuff or did you tear it all out? Vintage air?

I just got everything fitted I am gonna redo the padding befor final install. There is a place by me that sells the padding with a foil backing to better insulate so I will probably use that. It went in supprizingly easy once i figured out how to worl it under the cage.Kel Fab Creations wrote:Did you reuse the padding on the vinyl? That stuff was nasty looking.

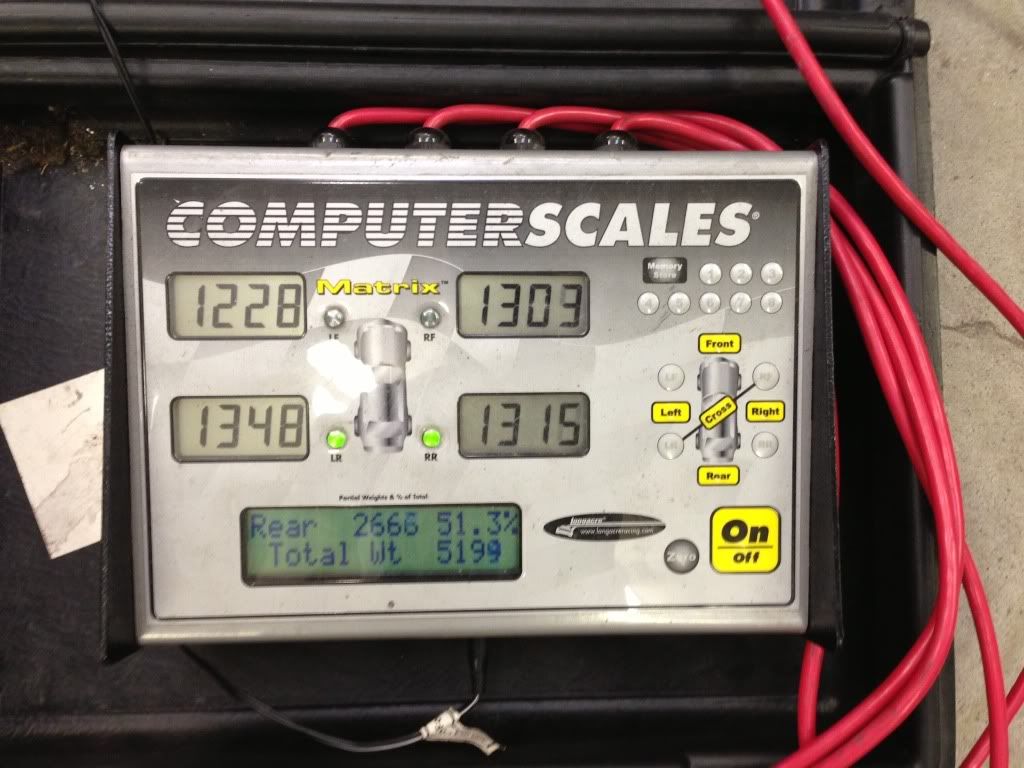

Wow we have similarly equipped trucks minus the cage. I would think I would be heavier. I did cut out all the internal sheet metal before caging. I wonder were I lost all the extra weight?Kel Fab Creations wrote:Dang! Mine weighs 5360 as is with a full tank. Good work.

I will let you know. Its not going to happen for a few months on my end anyway.Rmc wrote:I may be able to help you out soon on the aluminum panel stuff. I'm waiting on an invoice to roll through then I'm getting a stomp shear and a bead roll. It will be next month at the soonest. Just incase you don't find someone sooner. Robert

I second that. I have worked with Ronnie setting up some of his shocks on a friends race car. The way they are set up there is no low-speed damping. If you close the valves down to fix that it gets very harsh. Ronnie stated that low speed could be put in them, but he does not believe that they need it and gets very grumpy when you bring the subject up. Due to the lack of low speed, we ended up running a much stiffer spring rate than I normally would. It kind of works, but it still has drawbacks.cs_drums wrote:I would just ditch the revolutions and put some regular C/O maybe a king IBP.