dtbback wrote:Wouldn't he gain more travel with clocking even though he's extended?

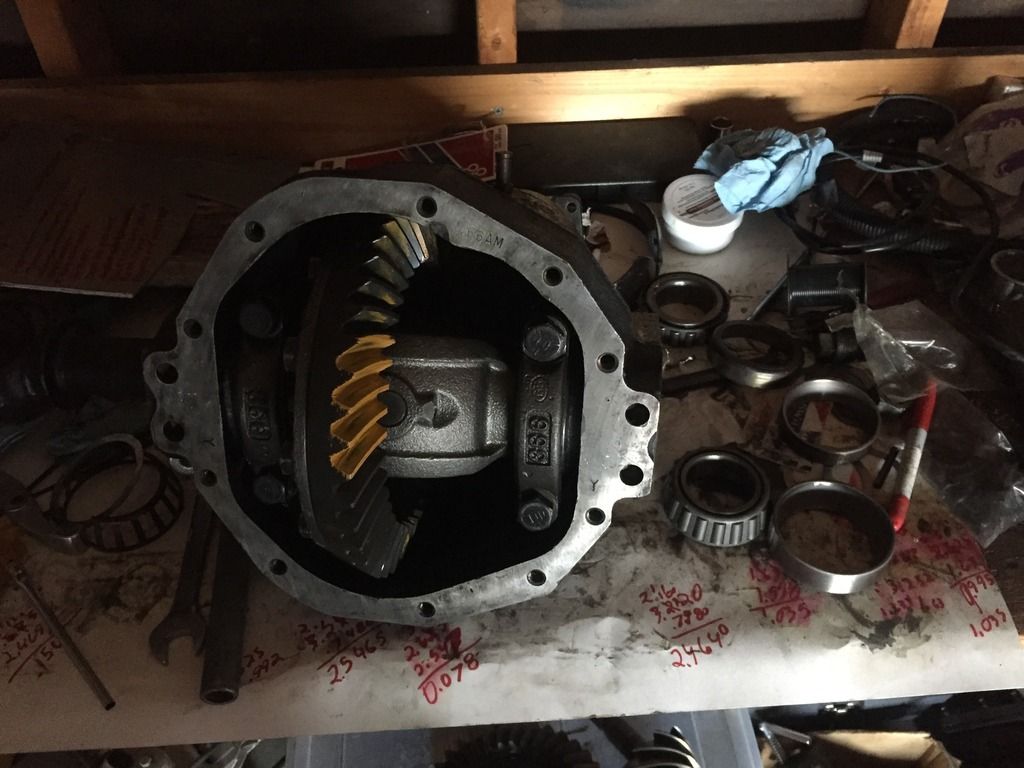

Clocking helps the clearance when one tire is up and the other is down. Basically the center u joint is raised by re clocking the diff ( from what I can remember anyway, it's been a few since I looked at it in front of me) but when the drivers beam is at tuck and the pass beam is at droop the axel hit the bottom of port window. With extended beams you usually run out of shock shaft before collision but it would depend on how high you place the full tuck position when placing the upper shock mount, height wise. When you cycle the front end be sure to check tuck on both, droop on both, driver up pass down, pass up driver down. You will recognize these 2 key locations as areas that need attention.

Anyway for what it's worth I hope this helps clarify. Oh the next issue becomes the center u joint it self, don't forget to clearance the yolks.

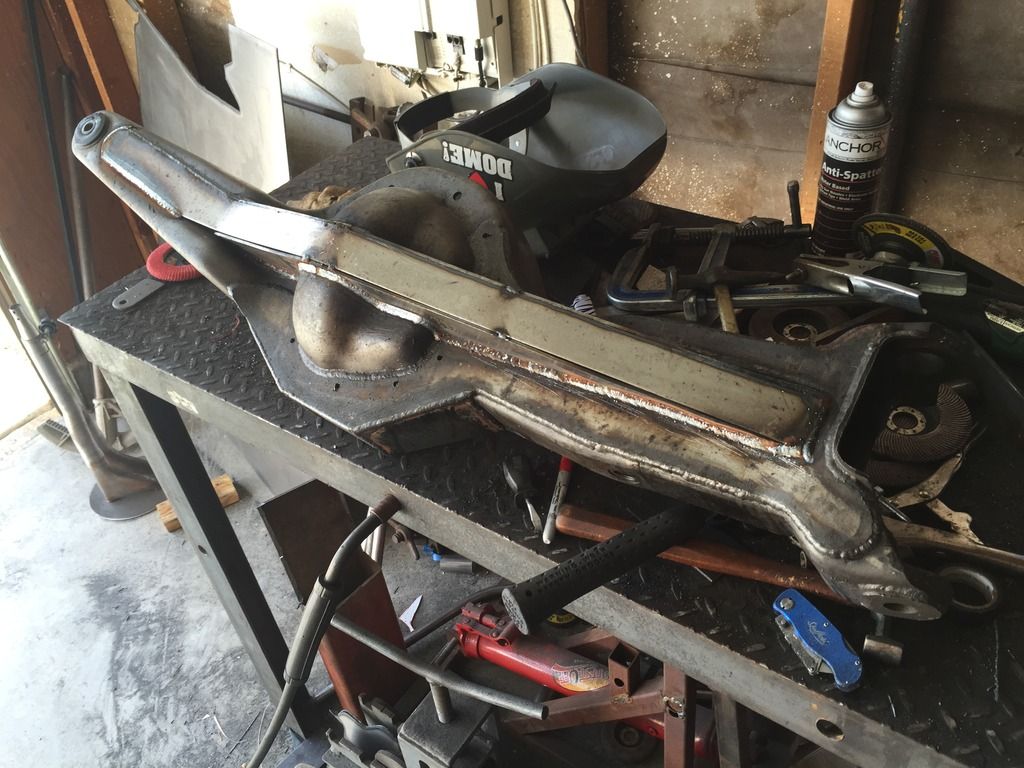

Beams look good, keep up the good work.